1235 aluminum foil is a commercially pure aluminum product belonging to the 1xxx series, with an aluminum content of not less than 99.35%. Due to its high purity, 1235 aluminum foil exhibits excellent ductility, corrosion resistance, electrical conductivity, and barrier performance, making it a widely used material in packaging and industrial applications.

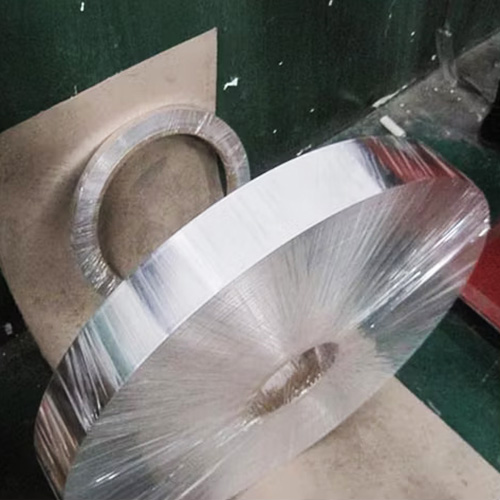

One of the primary characteristics of 1235 aluminum foil is its outstanding formability. The high aluminum content ensures excellent softness and elongation, especially in the O (annealed) temper. This enables the foil to be easily processed into thin gauges and complex laminated structures without cracking. The material’s flexibility and uniform grain structure also contribute to stable rolling performance and reduced surface defects.

In terms of barrier properties, 1235 aluminum foil provides effective protection against light, moisture, oxygen, and contaminants. These characteristics make it particularly suitable for packaging applications that require high sealing integrity and product preservation. Additionally, the foil offers good thermal conductivity and can withstand a broad range of temperatures, supporting both hot-fill and cold-storage conditions.

Although 1235 aluminum foil has relatively lower mechanical strength compared with alloyed grades such as 8011 or 8006, its high purity ensures superior surface finish and excellent compatibility with lamination, printing, and coating processes. This balance of softness, workability, and barrier efficiency makes 1235 aluminum foil an essential material in flexible packaging and insulation systems.