Sustainability and innovation are reshaping aerospace manufacturing. 3D printing, with its minimal waste and energy-efficient processes, has become a crucial component of environmentally responsible production.

The US Aerospace 3D Printing Market is setting benchmarks for eco-friendly innovation. Additive manufacturing enables reduced material consumption, lower emissions, and improved efficiency across the supply chain.

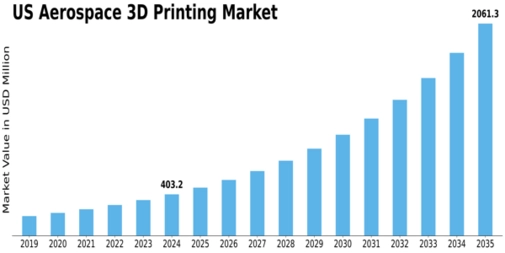

Market Growth and Analysis

Detailed market analysis reveals substantial growth due to sustainable practices and smart manufacturing technologies. The industry benefits from lighter structures and fewer production steps, aligning with green aviation goals.

Trends and Innovations

Major trends include the use of recycled materials, closed-loop manufacturing, and renewable energy integration into printing facilities. AI-based monitoring systems are optimizing part quality and minimizing production errors, ensuring precision and reliability.

Future Forecast

The forecast anticipates rising demand for sustainable aerospace solutions, with 3D printing playing a central role in reducing environmental impact. Research into biodegradable and recyclable composites will continue to enhance the market’s long-term prospects.

FAQs

1. How does 3D printing contribute to sustainability in aerospace?

By minimizing waste, reducing fuel use through lighter designs, and supporting recycling initiatives.

2. What are the main eco-friendly trends?

Recyclable materials, closed-loop production, and energy-efficient manufacturing practices.